Process Planning

Process planning is the foundation for our industry-specific solutions. Our platform includes modules to control, analyze, monitor, visualize, warehouse, and integrate, and combines them into high-value applications. we provide solutions which are scalable, flexible, and easy to integrate with existing business and plant infrastructure, our solutions can help you manage your most challenging advanced control problems is easy to configure, understand, and integrate with the rest of your process control system, all our models are scalable to achieve optimal operations, our solutions has been proven on hundreds of most complex and challenging control problems.

At Varad Consultancy we develop standardized workflows to operators to ensure the highest possible production quality and regulatory compliance. By modeling your manufacturing process to drive out variability, we propel continuous improvement initiatives by providing new ways to analyze process data.

- Seamless migration to pull-based replenishment.

- 100% visibility up and down the supply chain

- Complete supply-chain communication and collaboration

- Actionable business intelligence for all aspects of supply chain operations

- Significant reductions in raw material, WIP and FG inventory

- Increased operational ease and productivity Sizeable reductions to inventory carrying costs

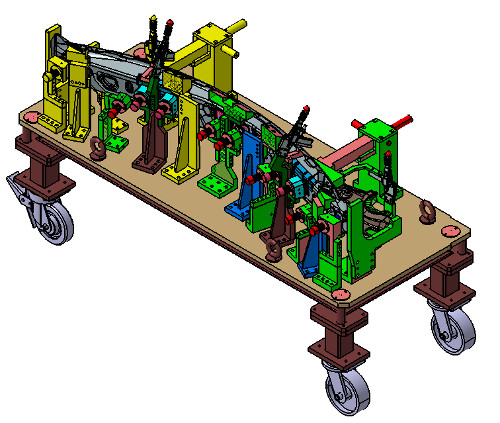

SUB-ASSEMBLY CHECKING FIXTURES

Fixtures and gauges available for a large variety of plastic and metal parts such as: Instrument panels, Interior trim, Seating, HVAC, Chassis components, Body panels, Door seals, and trim.

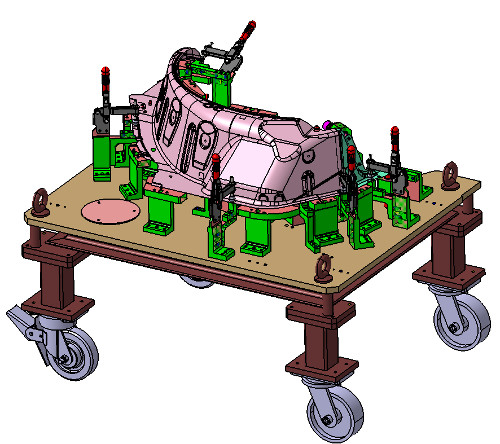

These fixtures control the components composing a rear lamp – or headlamp -, that is the housing and lens of the part. possibility of mounting the trunk and fender fixtures together, to check the proper fitting of both parts on the car.

All checking fixtures are designed for accuracy, repeatability and reliability with a strong focus on operator ergonomics. Varad Consultancy offers assembly and checking fixtures for vehicle frames and body sub-assemblies, single component fixtures for all metal and plastic parts, flush and feeler gap checking, mating part simulation and three axis true position probing.

Headlamps and rear lamps are components particularly difficult to check: apart from their dimensional conformity, they must be able to stand the climate and vibration conditions they will exposed to during the car useful life. Consequently, we propose to our customers three types of fixtures for these parts: complete checking fixtures – for lamps assemblies -, test fixtures – to be used on test laboratories -, and sub-assemblies checking fixtures – for the lamps components.

Headlamps and rear lamps fixture usually have a number of dial indicator points ranging between 6 to 12 points, which implies a relatively long cycle time. Using CAPTOR-S for this kind of fixtures helps reducing the risk of faulty measurements, the cycle time, and thus helps repaying on a shorter term the checking fixture.

Our checking fixtures are produced in aluminum, the components submitted to wear-and-tear are produced in steel. Tolerances for RPS (fixation points) and dial indicator points: ±0.05mm. Tolerances for simulation blocks: ±0.1mm.

Minimum documentation Delivered: dimensional report of your checking fixture, 2D assembly drawing, assembly CAD. Optional documentation: R&R report, user manual, stabilization certificate.

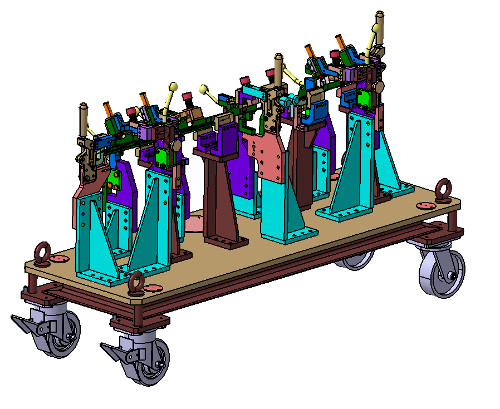

MANUFACTURING-ASSEMBLY

Advanced material technologies is utilised in development of each and every machine part, appropriate quality checks are performed at each stage of production. Due to the diverse nature of robots, integration in a variety of areas is made possible. Areas include virtually every industry and robotic application including:

- Precision part handling

- Arc welding

- Assembly

- Clean room

- Coating

- Dispensing

- Material cutting (laser, plasma, & waterjet)

- Material handling (diecast, machine loading, packaging, palletizing, part transfer, & press tending)

- Material removal (deburring, polishing, & sanding)

- Spot welding

With integration, adherence to established quality controls and assembly practices are easily maintained. Whether retrofitting an existing machine or working with a concept for a clean sheet design, Setpoint has a proven track record of providing turn-key robotic systems.

1.Inspection of inwards parts – The manufactured parts are received from variour suppliers and is inspected thoroughly to meet the tolerences specified by the costumer.

2.Painting – after the parts are certified, they are put for painting/ coating process.

3. Assembly- After the paint is completed, the assembly teams starts the assembly of the fixture as specified in the GA drawing.

During the assembly process the team has to take care of various aspects like tolerances maintenance, paint quality, Shimming adjustments and torque